The Toyota Forklift error code 01-6 is an alert of something wrong with your Toyota Forklift.

The E01-6 is either detected via the OBDII code reader or pops up in the forklift’s control panel display.

This article here shares complete information on the E01-6 fault code on Toyota Forklift – what does it mean, how to reset it, and how to troubleshoot.

Error Code E01-6 on Toyota Forklift

Error Code E01-6 on a Toyota forklift indicates an O2 sensor heater open abnormality.

The O2 sensor measures the oxygen content in the exhaust gases and provides feedback to the engine control unit (ECU). This information helps the ECU adjust the air-fuel mixture to optimize combustion efficiency. The heater is responsible for heating the O2 sensor to its operating temperature quickly, allowing it to generate a voltage signal.

An O2 sensor heater malfunction can have several effects on the forklift’s performance:

- It can lead to inaccurate readings from the O2 sensor, causing the engine to run inefficiently. This can result in decreased fuel efficiency, reduced power, and increased emissions.

- It may prevent the engine from entering closed-loop operation, where it relies on the sensor’s feedback for precise fuel control.

A properly functioning O2 sensor and heater allow the engine control system to make accurate adjustments, leading to better fuel economy, performance, and reduced emissions. Ignoring or delaying the repair can result in decreased efficiency, increased fuel consumption, and potential damage to other engine components over time. Therefore, it is important to address the issue promptly and have it resolved by a qualified technician or service center.

Probable Causes

Toyota Forklift O2 sensor heater open abnormality can occur due to one of three reasons, triggering the E01-6 code.

- O2 sensor defect – refers to a failure of the oxygen sensor

- Harness defect – refers to a wiring issue, such as a loose or broken connection

- Engine controller defect – refers to a failure of the engine control module (ECM) or electronic control unit (ECU)

Resetting Guide

Resetting Toyota Forklift fault code E01-6 is a quick and easy fix to address an issue, but if it persists, it may indicate a faulty part or sensor that needs replacement.

Here are the steps on how to reset the E01-6 error code on a Toyota forklift.

- Disconnect the negative battery terminal for 10 seconds.

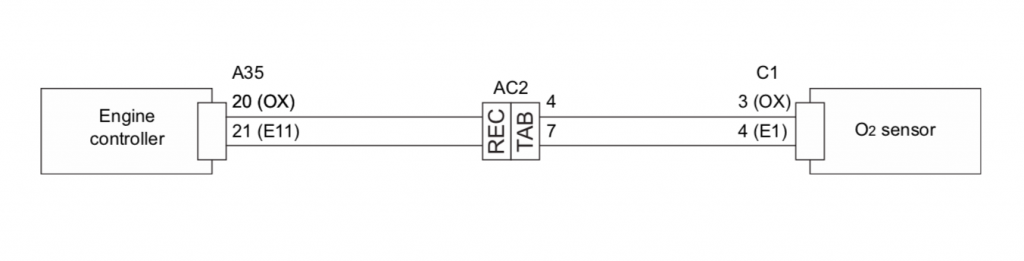

- Inspect C1 and AC2. Check for any loose or broken connections, as well as signs of water entry or moisture damage.

- Reattach any disconnected connectors and then reconnect the battery’s negative terminal.

- Start the engine.

- This will reset the Toyota Forklift E01-6 error.

Troubleshooting Guide

In some cases, following the aforementioned reset instructions can resolve the error. However, if the error persists, it is necessary to proceed with troubleshooting to identify and address the underlying issue. Follow the inspection process in sequential order.

1). O2 Sensor Individual Inspection

Carry out an individual inspection of the O2 sensor. The O2 sensor is responsible for measuring the oxygen content in the exhaust gases, providing essential feedback for optimal fuel-air mixture regulation and emission control. A defective O2 sensor leads to poor fuel economy, increased emissions, and performance issues.

To conduct the inspection, follow these steps:

a). Turn off the ignition key switch.

b). Disconnect connector C1.

c). Connect connector A35.

d). Take the O2 sensor readings.

e). Ensure the following standard readings are within the specified range:

| C1-2 ~ C1-1 | 13 ~ 16 Ω (20°C) |

| Resistance between terminals C1-2 and C1-1 should be between 13 to 16 Ω at a temperature of 20°C. | |

A faulty O2 sensor can also trigger E01-5. Read more about Toyota Forklift error code E01-5 here.

👉 If the error code is resolved, it’s good.

Otherwise, move to the next inspection step below.

⬇️⬇️⬇️

2). O2 Sensor Heater Power Voltage Inspection

Inspect the O2 sensor heater power voltage. The O2 sensor’s heater is responsible for reaching and maintaining the optimal operating temperature of the sensor. The heater ensures the proper functioning of the O2 sensor.

To perform the inspection, follow these steps:

a). Turn off the ignition key switch.

b). Disconnect connector C1.

c). Connect connector A35.

d). Start the engine.

e). Take voltage readings. The expected voltage readings should be between 8 to 16 V:

| C1-2 ~ Frame | 8 ~ 16 V |

A poor voltage power in the O2 sensor heater can also trigger E01-4. Read more about Toyota Forklift error code E01-4 here.

👉 If the error code is resolved, it’s good.

Otherwise, move to the next inspection step below.

⬇️⬇️⬇️

3). Harness Continuity and Short Circuit Inspection

Inspect the harness for continuity and short circuits. Harness continuity refers to ensuring that there is a continuous flow of electrical current through the wiring harness without any breaks or interruptions. Short circuits, on the other hand, occur when there is an unintended connection between two wires or terminals, causing electrical current to flow where it shouldn’t.

Inspecting the harness for continuity and short circuits ensures proper electrical connections and prevents issues such as electrical malfunctions, circuit failures, or potential damage to the forklift’s components.

To perform the inspection, follow these steps:

a). Turn off the ignition key switch.

b). Disconnect connector A35.

c). Disconnect connector C1.

d). Check for continuity.

e). Ensure there is continuity between A35-6 and C1-1, indicating a proper electrical connection.

f). At the same time, there should be no continuity between A35-6 and Frame, ensuring there are no unintended connections.

| A35-6 ~ C1-1 | Continuity |

| A35-6 ~ Frame | No continuity |

Summary Points

The Toyota Forklift error code E01-6 indicates an O2 sensor heater open abnormality.

The O2 sensor measures the oxygen content in exhaust gases, providing feedback to the engine control unit (ECU) for optimal fuel-air mixture regulation.

The error can be caused by a defective O2 sensor, a harness defect, or an engine controller defect.

Resetting the error code involves disconnecting the negative battery terminal and inspecting connectors C1 and AC2 for loose connections or water damage.

If the error persists, further troubleshooting is required. This includes individual inspections of the O2 sensor, checking the O2 sensor heater power voltage, and inspecting the harness for continuity and short circuits.

Proper maintenance and timely resolution of the error are crucial to ensure optimal performance, fuel efficiency, and reduced emissions in the Toyota Forklift.